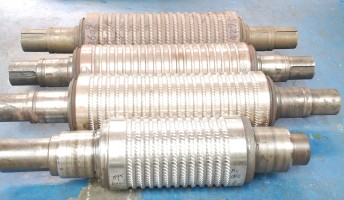

Reinforcing Bar Roll

Han Chun Mechanical is the first professional factory in Taiwan which successfully use CAD/CAM to combine with CNC highly precise machines to do processing work for various kind of rolls. When the experienced technical engineers are matched by professional roll processing machine to product high-quality rolls, we expect to save the operation time of steel refinery factory, decrease the production of non-conforming products, and extend the life of rolls.

Range of Processing:

- The hole shape processing of different kinds of rolls and slotting of rolls for steel refinery factories(including different kinds of rolls of different steel refinery factories, such as reinforcing bar, wire materials, flat iron, angle iron, slot iron).

- Various kinds of steel refinery equipment parts and other mechanical metallic parts.

Rebirth of Rolls’ Hard Face

In order to meet the need of general steel refinery factories to lower the cose, we adopt the Untied Stated’ Cincoln automatic welding machine, which uses the American imported welding materials, Welding/Cincoln/Stood, to carry out welding work for the worn rolls and let them reborn. It really meets the needs of different levels of customers.

Gear

The company started from the manufacturing of large-size gear and gearbox. We have staff of rich experience and the most professional mechanical equipment. Through the professional planning and design, we can offer a production mode of consistent operation, no matter from the manufacturing of gears of different specifications, down to the assembling of the whole gearbox. We want every step to be under the quality control, with an expectation to reach the industrial needs off low abrasion, low noise and long life.

Characteristics:

- The British-made Sunderland gear machine can do some special processing work, such as straight gear, inclined gear, shape gear, etc. Maximum processing diameter: 2150mm; Maximum processing width: 500mm

- Positive 30 degree pressure angle gear, most suitable for the use in heavy-load rotation.

- High preciseness, low abrasion and low noise, which are helpful to the promotion of the preciseness of products.

- Processing and shaping at one time. Make sure of the precise thickness of each gear. It can effectively extend the life of gear and the smoothness of rotation.

- The unique design of circulation oil slot can assure the complete lubrication of gear gap.

Precise Grinding

The machine does the processing work for the main shaft, main shaft of grinding wheel, X shaft, Z shaft inside NC-styled CNC, extremely precise external diameter grinder, and the internal hole of large-size work piece. It can find out the core easily when grinding the ends and surface. It takes the grinding of high preciseness as the aim. It can shorten the time for loading and unloading of materials, and make the real circular shape more precise. And the internal and external diameter, end and surface, and also the back can be completed continuously at the same time. This is another characteristic of the machine.