LARGE GEAR

The demands of different specifications require the same preciseness and professional standard.

We started from the manufacturing of large-size gear and gearbox. We have staff of rich experience and the most professional mechanical equipment. Through the professional planning and design, we can offer a production mode of consistent operation, no matter from the manufacturing of gears of different specifications, to the assembling of the whole gearbox. We want every step to be under the quality control, with an expectation to reach the industrial needs of low abrasion, low noise and long life.

- The British-made SUNDERLAND gear machine can do some special processing work, such as straight gear, inclined gear, A shape gear, etc.

Maximum processing diameter: 2150 mm Maximum processing width : 500 mm - Positive 30° pressure angle gear, most suitable for the use in heavy-load rotation.

- High preciseness, low abrasion and low noise, which are helpful to the promotion of the preciseness of products.

- Processing and shaping at one time. Make sure of the precise thickness of each gear. It can effectively extend the life of gear and the smoothness of rotation.

- The unique design of circulating oil slot can assure the complete lubrication of gear gap.

- British-Made SUNDERLAND Gear Machine

- German-Made FROMAG Key Slot Machine

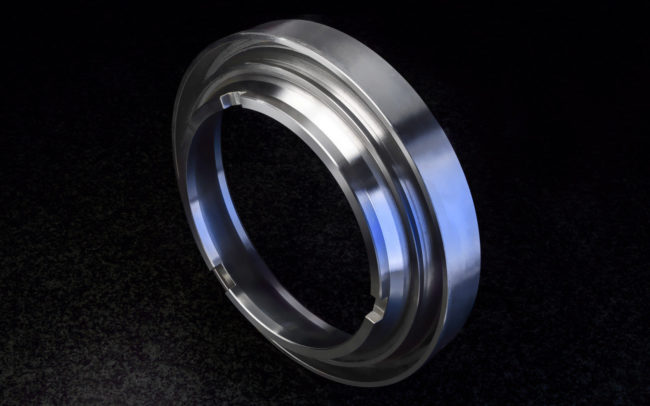

ROLLING MILL ROLLERS

Use order to balance chaos. Use a warm heart to quench steel.

Han Chun Mechanical is the first professional factory in Taiwan which successfully use CAD / CAM to combine with CNC highly precise machines to do processing work for various kinds of rolls. When the experienced technical engineers meet professional roll processing machine to produce high-quality rolls, we expect to save the operation time of steel refinery factory, decrease the non-conforming products, and extend the life of rolls.

- The hole shape processing of different kinds of rolls and slotting of rolls for steel refinery factories (including different kinds of rolls of different steel refinery factories, such as reinforcing bar, wire materials, flat iron, angle iron, slot iron).

- Various kinds of steel refinery equipment parts and other mechanical metallic parts.

- Japan-made IKEGAI CNC Roll Processing Special Machine

- SAN SHING CNC 2m、3m、4m Lathe

- KINGSTON CNC Lathe

- DMG-MORI multi-axis CNC Lathe

- ATOMAT AT730E

NODE

One type but various changes

Reinforcing bar is an indispensable and important material in a construction project. In recent years the government has strict requirements for the materials of public project and construction project. Regarding the inspection on the quality of reinforcing bar products and their radiation volume, the government pays much attention. In order to match with the steel refinery factory, this company is able to make the products more competitive on their quality and quality control, We invested plenty of money to purchase the Japanese IKEGAI and Italian ATOMAT machine especially for node processing. And we technical interflow with some steel refinery factories in Japan, such as Sumitomo Steel, Kuo Kuang, etc. to promote the quality of node processing techniques. Bedises, in times of node jumping of rolling wheel, we carve at the carving grain the code of each steel refinery factory in order to show our responsible attitude towards its reinforcing bars produced.

- Range: D10~D57

- Processing lines including : Straight 、Inclined、Cross、Z shape、Spiral pattern,etc.

- Italian ATOMAT Node Processing Machine

- Japan’s IKEGAI Processing Machine Especially for Node

- Vertical Node Processing Machine (self-developed RUEYTONG CNC discharge processing machine)

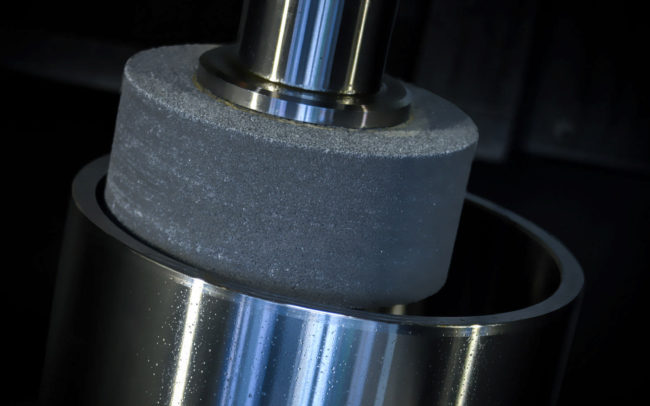

PRECISE GRINDING

Time can wear down everything, but can also achieve extraordinary art.

In recent years the highly efficient and highly precise grinding industry has been widely used in the production line of various field, in the aviation and space industry, parts of car and motorcycle, precise ceramics of some highly hard and highly precise products, such as the stone material for construction, woodwork material for construction, processing of gem, etc. All of these belong to the processing range of precise grinding. With the strategy to promote the traditional industry and the principle to accelerate the standard of customer, we have purchased from Japan the TAIYO vertical CNC grinder so as to positively join our products in the list of development of the high-quality and high-preciseness grinding products.

- This machine does the processing work for the main shaft, main shaft of grinding wheel, X shaft, Z shaft inside NC-styled CNC, extremely precise external diameter grinder, and the internal hole of large-size work piece. It can find out the core easily when ones the ends and surface. It takes the grinding of high preciseness as the aim. It can shorten the time for loading and unloading of materials, and make the real circular shape more precise. And the internal and external diameter, end and surface, and also the back can be completed continuously at the same time. This is another characteristic of the machine.

- Japan-Made TAIYO Vertical CNC Grinder